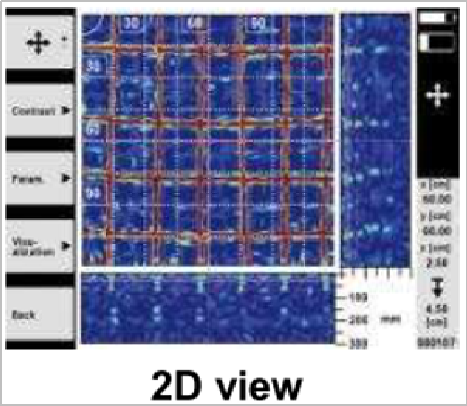

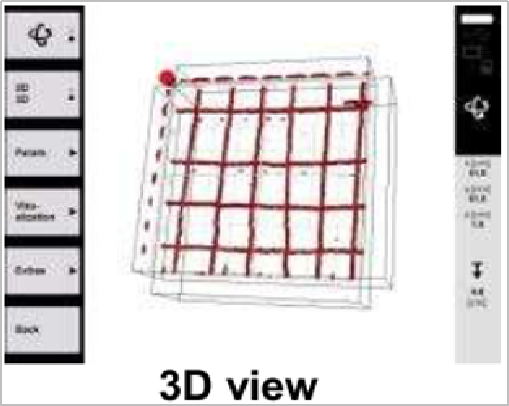

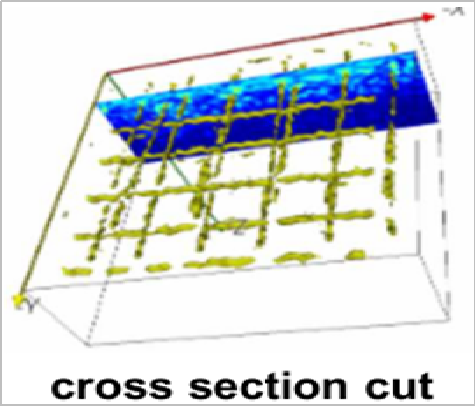

For some of the old infrastructure around us many a times as build drawings are not available, on some sites actual steel provided details needs to be cross verified for missing reinforcement if any or at times exact locations of rebars in concrete are specifically required to implement repair systems recommended. For this sanrachana maintains and provides Ground Penetrating Radar – GPR scanner services and Ferro scan system equipment’s. They easily scan the RCC element from over the surface and determines location and sizes of rebars to a depth of up to 300 mm; moreover the output of those is readily available on site after scans in top view, section view or 3-D form for analysis; thereby providing for vital design inputs and to decide on further course of action for strengthening and retrofitting system. This helps during structural modification also to decide exact location for core and cuts required to be taken in the structure for any service requirements.

Cracks are traced and opened in v groove manner, cleaned and sealed with epoxy putty and grouting nozzles non return type are fixed at specified intervals which later are injected with epoxy grout under pressure till rejection.

FRP Systems are used to enhances structural capacity of members in shear, flexure, compression, to aid in blast mitigation, upgrades for seismic loads and to controls propagation of existing cracks.

Application of FRP Systems is mainly

Sanrachana designs retrofit systems and provides application solutions with Glass, Glass Aramid composite and High strength carbon fabric systems woven in uni direction, bi direction and diagonal pattern with density ranging up to 1200 GSM with wet layup system.

Fiber-mesh Reinforced cementitious mortar (FRCM) system involves a specially treated fiber mesh sandwiched in between a special grade high strength inorganic repair mortar.

Sanrachana has trained applicators to apply FRCM layups in layers of about 6 to 8 mm thickness each over damaged structural elements. The High strength, light weight and non corrosive FRCM system results in long lasting repairs. This is a durable alternative to the GI mesh based guniting system which used to degrade easily due to corrosion.

External Post tensioning Systems installed on RCC Girders and Slabs. PT can be done with both FRP and Convensional system

Sections enlargement or reinstatement involving thickness ranging from 40 to 100 mm thick ness is generally done with high strength self levelling and compacting micro concrete mixes. Reinforcement is provided in form of regular rebar cage, hard wire stainless steel mesh or metallic fibres dispersed in microconcrete mix. Shear keys are provided as usual for effective transfer of load.