For a structure under repairs steel is usually affected by corrosion; loose rust scales are removed preferably all around the bar using abrasive tools or sand blasting and stabilized for rust formed with suitable rust convertors; then a protective coating is applied over the rebars such as alkaline cement polymeric coat, epoxy phenolic coat or zinc rich paint, etc. Considerably lost rebar sections are replaced with new bars with sufficient lap on both ends.

The lost RCC Section is then rebuilt using PMM, Thixotropic repair mortar or micro concrete casting with bond coats or shearkeys used as an effective medium for transfer of loads.

Structural cracks are opened in v groove manner, cleaned and sealed with epoxy putty and grouting nozzles are fixed at specified intervals.

The injection ports are then filled under pressure with epoxy grout till rejection. To improve upon the microstructure of concrete pressure grouting either with microfine cement, epoxy, very low viscosity epoxy grouts is carried out for RCC elements such as columns, beams and slab. Gravity flooding at a specific dosage with monomer’s is carried out from over the slabs.

Further existing structural cracks are to be strengthened by using various repair and retrofit systems

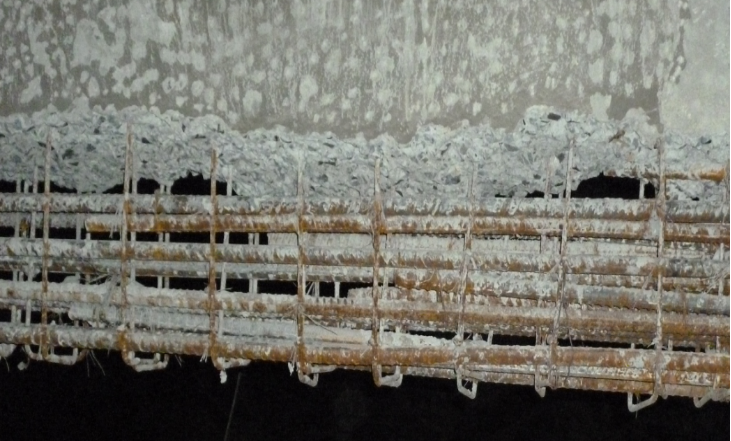

Sometimes the disintegrated RCC element or original construction is having problems to such a extent that the full depth of section needs to be addressed for repairs; the above image shows such problem due to congested reinforcement. The section was casted with micro concrete for better penetration and retrofitted in shear with FRP strips. To fill in other joints and honeycombing extensive epoxy grouting was carried out.

Hot Wrap system involves a specially treated carbon fiber mesh sandwiched insitu between a special high strength inorganic mortar with hand layups in layers of about 6 to 8 mm thickness each.

This repair system is suited for application in areas of high ambient temperatures of about 100°C where organic epoxy systems are ineffective such as structural members near furnaces, hot coking coal beds, incineration chambers, Chimneys, etc. Sanrachana with its trained applicators is well versed with installation of such systems.