Problem:

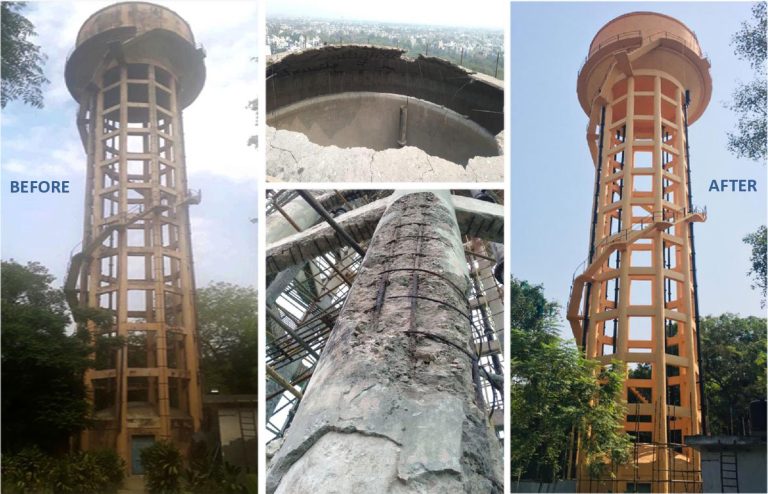

Main frame of the water tank was badly damaged due to corrosion of the embedded steel.

Solution:

Preparation of a working platform below the mainframe was a major challenge involved in the project.

Problem :

Solution:

Problem:

Solution:

Problem:

Solution:

Problem:

4 mega RCC tailing thickener tanks of a mining company, having surface area of 25,000sqft eachwere observed with issues likedeterioration of RCC supporting structure because of corrosion, pitting of concrete surface and leakages through expansion joints.

Diagnosis:

The slurry stored inside the sedimentation tank was acidic. Due to continuous drippingofacidic slurry on RCC elements, progressive corrosion damage was observed. The main source of leakage was the expansion joint. Eventually over time, the inner protective coating of the tank was giving away, exposing the reinforcements inside the surface of the tank to acidic slurry.

Solution:

Problem:

50-year-old RCC OHT of 43 m height and 3,00,000-liter capacity showing following defects:

Solution:

Design and erection of scaffolding, implemented with meticulous safety plan for work-from-height