Problem:

Solution:

Problem:

Solution:

Problem:

Solution:

Problem:

Solution:

Problem:

Solution:

“Sanrachana ensured timely completion and co-operated to adjust our shut down requirements. The job was executed as per contract specifications and by following stringent safety norms.” Engineer incharge, NTPC Faridabad.

Problem:

Solution:

Problem:

Solution:

Problem:

Extensive micro-cracking and corrosion in 25-year-oldRCC coke oven structure of a steel plant due to constant exposure to 100°C temperature.

Diagnosis:

Repair system should be stable under sustained high temperature exposure. Conventional repair systems based on organic materials are unsuitable for this type of exposure.

Solution:

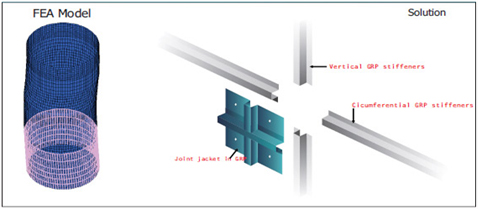

Problem:

Extensive corrosion damage on columns, beams and coal stacking slab. Conventional jacketing not possible due to immovable service line network.

Diagnosis:

Corrosion damage needs to be rectified, low strength of existing concrete needs to be improved, without increasing cross section area.

Solution:

Problem:

Lift shaft wall showed cracks. Deflection and honey combing was noted. Staircase columns showed local buckling and sagging of beams.

Diagnosis:

Cracks on lift shaft wall was due to wind pressure. NDT showed that concrete quality was poorfrom 60m to 90m height. Major issue was improper handling of slipform formwork, which also explains the deflection of the tower.

Solution: