Problem:

Solution:

The job was carried out in short time intervals of 2 to 3 hours in late night hours. Traffic management on roads below metro lines was a major challenge. Full scale load testing was done successfully.

Problem:

Solution:

Problem:

Solution:

After completion of the retrofitting work the bridge was successfully tested for IRC Class 70 R loading condition. Chehru bridge on NH-01 part of the original Grand Trunk Road is a vital link between Jalandhar and Phagwara in Punjab

Problem:

Solution:

Problem:

Solution:

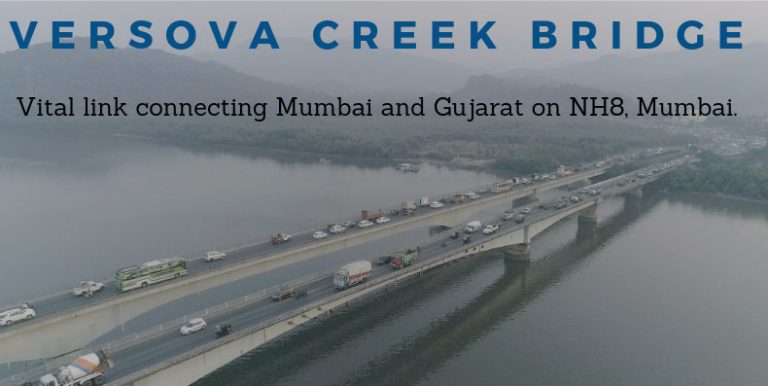

The bridge connects Mumbai and Gujarat, making it an essential link in NH8. Apart from Sanrachana, experts like IIT Bombay, Ramboll, SMC and IRB were involved with NHAI on this project.

Structure:

50 years old RCC aqueduct in Madhya Pradesh (Central India). Longest aqueduct carrying water in the region

Problem:

Solution:

One of the Largest CFRP – SRM – CWrap 200 – application on any single project – 22000 sq. meters of wrapping on piers and different RCC elements.

Problem:

Cracks of varying intensity observed in almost all 10 girders per span, in the nearly 60 span 1.5km flyover on Eastern Express Highway

Diagnosis:

Cracks in girder were primarily due to reduced shear capacity, causing combined shear-flexure cracks. Alligator cracks seen in slab were to be sealed to prevent corrosion damage in future.

Solution:

Problem:

Analysis and NDT revealed severe steel deficiency in piers and cross-girders of this bridge. A new steel pedestrianfootpath was meant to be anchored to the structure. Overall steel deficiency and additional loads of footpath was to be tackled.

Solution: